The Keys to Concrete Longevity

Category: Build-Remodel-Topics, Industry-Statistics11/05/2019

By Lacie Johnson, Communications Intern

Concrete provides the foundations for where we live, work, drive and walk. As we head into winter, the sand-and-salt season for roads, it’s important to know the do’s and don’ts of concrete maintenance to ensure durability and longevity. With tips from North Dakota Ready Mix & Concrete Products Association, this blog is designed to inform you on steps to take during the construction process and into the future to maintain beautiful concrete.

Utilize Proper Mix – Qualified Contractor – Proper Placement

Your local concrete supplier has engineered mix designs to meet every application. Choosing the right mix for your project is just as critical as choosing the right contractor for the job. This will all help ensure the placement of your new concrete surface is done professionally. Ensure proper base preparation for soundness and drainage as well as placement techniques and application of a concrete curing agent. For more details, visit ndconcrete.com.

Concrete can be vulnerable to damage when exposed to salts and other deicing agents. Avoid using any type of deicer on your concrete, and make sure to read the labels of products sold that claim to be “concrete friendly.” If the ingredient list shows magnesium chloride or potassium acetate, do not use. Homemade vinegar deicing sprays, prevalent on the internet, are not good for concrete as vinegar is an acid. Also avoid using fertilizer as deicers as it too contains substances that can chemically attack concrete.

Your best and safest bet is to utilize plain sand for traction. Minimize parking of vehicles on driveways when possible as salts and deicing chemicals will drip onto the pavement. Products applied to public roadways by local and state government agencies will eventually dry but will reactivate when moisture occurs again. The same goes for materials applied on public and private parking lots. Repeated freeze/thaw cycles will inflict damage to the surface layer of concrete if left exposed to salts and deicers.

Seal Your Concrete

In our northern climate, concrete is subjected to several freeze/thaw cycles per winter, so the applying a penetrating concrete sealer is a great way to protect your investment. Concrete sealers provide a barrier against water and deicing agents and extend the service life of concrete pavement. Once freshly placed concrete has cured for 28 days, a concrete sealer can be applied, if weather conditions allow:

- Apply sealers when the outside temperature is within 50-80 degrees Fahrenheit. Failing to do so may lead to discoloration, bubbling or coating failure.

The best time of day to apply sealer is the late afternoon or evening. At this time of day, the sun is setting, the air temperature is cooler, and the surface is less exposed to UV rays. Twenty-four hours prior to sealing the concrete surface, clean the area with a hose and cleaner/degreaser:

Washing the Surface

Cleaner/Degreaser

Cleaning Surface Cracks

Prior to applying the sealer, sweep pavement to ensure there are no loose materials. If necessary, create a boundary to limit the possibility of traffic. Look for professional-grade concrete sealers that are either silane and/or siloxane-based products. If unsure, ask your local contractor supply store, that specializes in concrete construction.

Applying a concrete sealer can be performed as a do-it-yourself project and generally can be completed in a few hours, depending on the size of your pavement. Sealers can either be sprayed or rolled on your concrete. Or you can also choose to ask your contractor for a quote on sealing your pavement. It is important to note most surface defects caused by salts and deicing agents are aesthetic in nature and not structural. A few easy steps can help mitigate potential issues.

Professional-Grade Sealer and Application Tools

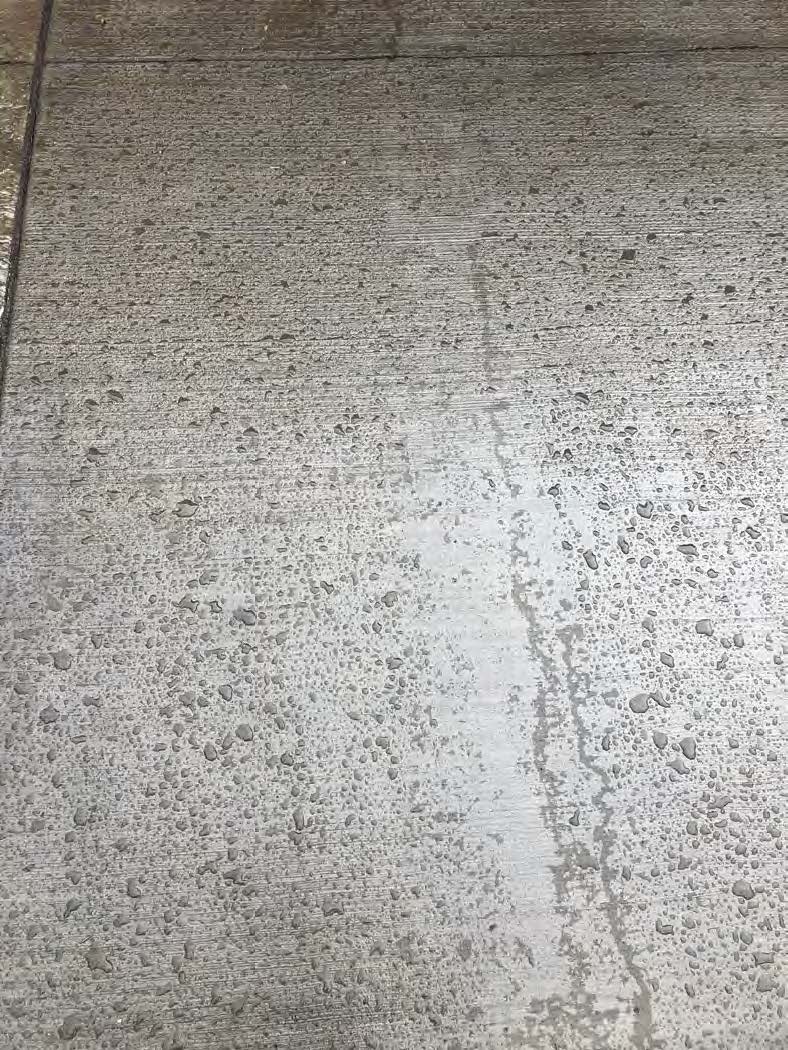

Reapply every two to four years, or as recommended by the manufacturer. You can spot check your concrete by pouring water on it. If the water is absorbed, the concrete will darken, and you will need to reapply. If the water beads up and sheds off the surface, your sealer is working.

Water Beading

Be Educated on The Issues – Manage Your Expectations

Your investment in concrete will add value and improved aesthetics to your property for years to come. Like any building material exposed to the elements, concrete will require routine care and maintenance to maximize its service life. For more information on concrete maintenance and homeowner tools, visit ndconcrete.com.